Linear guide rails are the backbone of precise, repeatable motion in automation, CNC, robotics, and many industrial machines. Choosing the right rail structure affects load capacity, speed, stiffness, and cost. Here we present the top 5 most popular linear rail structures, explain how each works, outline pros and cons, and suggest where to place illustrative images to help readers visualize the differences.

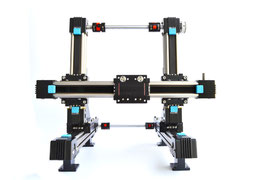

At CCM Rails, we offer modular motorized linear stages that you can configure in countless ways—such as XY, XYZ, or other multi-axis arrangements—to meet your exact application needs. Below, we highlight the top 5 most popular stage combinations, but you’re free to choose any series, travel length, and lead-screw pitch on each axis to build the perfect stage for your project.

-

Modular Configurations: Configure as XY, XYZ, or custom multi-axis layouts by selecting the appropriate stage family, travel range, and lead-screw pitch per axis.

-

Top 5 Popular Combos: We showcase five frequently chosen combinations to help you get started—yet every system is fully customizable.

-

Protected Shipping: To avoid damage to bearings and other sensitive components, we ship multi-axis stages unassembled, complete with clear assembly instructions.

-

Stage Families: Explore our range of linear stage families—each engineered for different loads, speeds, and precision requirements.

-

Expert Support: Our engineering team can guide you through selecting the right family, travel, and lead-screw options so your stage performs reliably from day one.

Ready to design your custom motorized stage? Contact our engineering team for personalized guidance and a fast quote.

NO.1 : XYZ LINEAR STAGE

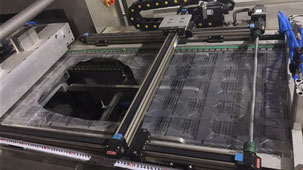

Glue dispensing is a prime application for our XYZ modular linear systems. While widely used in cookie and food production lines, these systems also play a vital role across diverse packaging processes in other industries. We offer a variety of linear rails tailored for glue-dispensing setups. A standout feature of our modules is the integrated cylindrical rotary joint, enabling 360-degree rotation for the rail. This full-range movement allows the dispenser head to reach any angle or position, improving coverage, accuracy, and cycle flexibility.

-

Versatile Industry Use: Ideal for food companies (e.g., cookie lines) as well as electronics, cosmetics, pharmaceuticals, and general packaging.

-

Custom Rail Options: Multiple rail families support different loads, speeds, and environmental requirements.

-

360° Rotary Capability: The built-in cylindrical device provides unrestricted rotation of the dispenser head—perfect for complex patterns or multi-sided applications.

-

Precision & Reliability: Smooth, backlash-free motion ensures consistent glue application and reduces waste.

-

Easy Integration: Modular design simplifies assembly, maintenance, and future reconfiguration.

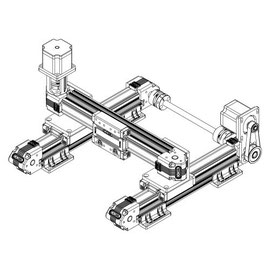

NO.2 : XY LINEAR STAGE

At CCM Rails, we deliver tailored automation solutions for the packaging industry. Our modular, flexible structures accelerate your project by reducing design time and lowering costs. Backed by decades of industry expertise, our team ensures reliable performance and seamless integration—so you can focus on production, not engineering hurdles.

-

Modular Flexibility: Pre-engineered components adapt to diverse packaging machines, minimizing custom design effort.

-

Cost & Time Savings: Leverage our proven solutions and extensive know-how to avoid trial-and-error and shorten lead times.

-

Decades of Experience: With years serving automation clients, we understand common challenges and best practices for packaging lines.

-

Reliable Support: Work directly with our engineering team for guidance on system selection, integration, and optimization.

-

Scalable Solutions: Easily expand or reconfigure systems as production needs evolve.

👉Ready to streamline your packaging automation? Contact our experts for a custom solution and fast quote.

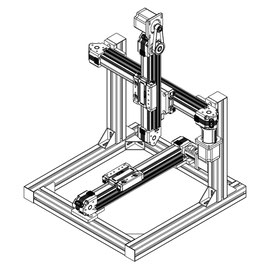

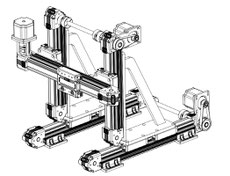

NO.3 : XY LINEAR STAGE-X AXIS VERTICAL

XY linear rail stages are widely used in laser and CNC machines thanks to their compact design and low-noise operation. By integrating a pre-engineered linear rail stage, you avoid the need to design and fabricate additional support structures or auxiliary metal parts. This speeds up development, improves precision, and ensures smooth, reliable motion from day one.

-

Plug-and-Play Integration: Prebuilt linear stages fit directly into laser/CNC frames, reducing engineering effort.

-

Low Noise & Smooth Motion: Precision guide rails minimize vibration and acoustic noise during high-speed cutting or engraving.

-

Compact Footprint: Slim profiles free up space and enable more compact machine layouts.

-

Reduced Design Complexity: Eliminate the time and cost of custom structural components—focus on machine performance instead.

-

High Rigidity & Accuracy: Engineered for minimal deflection under load, ensuring consistent machining quality.

-

Durability & Maintenance: Built-in seals and hardened surfaces offer long life with minimal upkeep.

👉Enhance your laser or CNC system with a ready-to-install linear rail stage. Contact our engineering team for tailored recommendations and a fast quote.

NO.4 : XYZ LINEAR STAGE WITH ALUMINIUM

At CCM Rails, many customers have developed automated drilling machines for light materials using our belt-driven linear guide rails. Our solutions enable precise, smooth, and reliable drilling operations without extensive custom design work.

-

Automated Drilling for Light Materials: Leverage our belt-driven linear guides to build machines that drill plastics, composites, foam, and other light substrates with consistent accuracy.

-

Smooth, Low-Friction Motion: The belt-drive system ensures quiet operation and minimal backlash—critical for repeatable hole placement.

-

Easy Integration: Pre-engineered linear modules fit seamlessly into drilling rigs, reducing design time and supporting faster prototyping.

-

Customizable Configurations: Select travel length, load capacity, and belt pitch to suit your application’s speed and precision requirements.

-

Proven Performance: Many clients report improved throughput and reduced maintenance when using our linear guide belt drives in their drill machines.

👉 Ready to automate your drilling process? Contact our engineering team for tailored advice on integrating belt-driven linear guides into your drilling machine design.

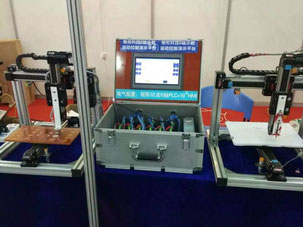

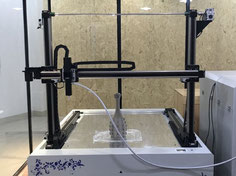

NO.5 : Dual Z axis gantry stage linear modules

3D printers are a prime application for our XYZ modular linear systems. With customizable rail lengths and an easy, professional assembly process, building an industrial-grade 3D printer is straightforward using our precision guide rails. Our modular design also simplifies adding or swapping multiple extruders for advanced printing needs.

-

Customizable Size & Travel: Tailor rail lengths and travel ranges to your printer’s build volume without complex redesigns.

-

Easy Assembly: Pre-engineered modules and clear instructions let you assemble the linear axes quickly and accurately.

-

Multi-Extruder Support: Integrate single or multiple extruder heads effortlessly—our modular stages handle the added load and maintain precision.

-

High Precision & Rigidity: Linear guide rails ensure smooth, low-friction motion for consistent layer accuracy and repeatability.

-

Scalable & Upgradable: Start with a basic XYZ structure, then expand or upgrade (e.g., add a fourth axis or tool changer) as your requirements evolve.

-

Reliable Performance: Robust construction and quality bearings reduce maintenance, keeping your 3D printer running longer with minimal downtime.

👉 Ready to design your industrial 3D printer with modular linear rails? Contact our engineering team for personalized recommendations and a fast quote.

CCM Linear Guide Rail Structure Design Tips

Optimizing your linear guide rail structures ensures reliable performance, easy assembly, and long-term durability. Use these design tips to leverage the full benefits of CCM’s modular linear rails:

-

Customizable Lengths for Versatile Configurations

-

Tailor rail lengths to your exact application requirements. Whether you need a short travel range or extended stroke, specify the dimensions to fit your machine layout and work envelope.

-

-

High Quality, Portable, and Maintenance-Free

-

Our rails are engineered for longevity and portability. Built with precision-ground surfaces and sealed bearings, they support multi-carriage setups flexibly and require minimal upkeep over their service life.

-

-

Integrated Nut Grooves in Aluminum Profiles

-

Aluminum extrusion profiles include T-slots or nut grooves, simplifying the fixation of linear rails and related components (sensors, brackets, supports). This modular approach accelerates assembly and adjustments.

-

-

Convenient Rail Mounting Features

-

Dedicated mounting brackets and fixtures enable quick installation of rails and modules. Use these ready-made mounts to align and secure rails accurately, reducing setup time and alignment errors.

-

-

Adjustable Carriage and Belt Tension Design

-

Carriage blocks are designed with easy-access tensioning points for belts and linear bearings. Quick tension adjustment maintains smooth motion and accuracy, even after extended operation or maintenance.

-

You may be interested in

What is a gantry robot?

CCM belt driven linear actuators are widely used in gantry system, from electronic assembly and electronic manufacturing to vision systems and industrial automation.

How to choose the right rail?

Looking for the right linear rail for your automation project? Discover how to choose the best belt-driven linear guide rail for load, speed, and precision needs. Expert tips included.

Write a comment