You can learn about load capacity considerations for belt-driven linear guide rails, including how to calculate them, factors that affect the limits, and best practices.

Discover key factors for choosing belt-driven systems over alternatives like ball screws, rack & pinion, and linear motors. Learn when belt drives shine and when to pick other options.

Learn what a belt-driven linear guide rail is, how it works, advantages, pros and cons, FAQs, and actionable tips for your automation projects.

Looking for the right linear rail for your automation project? Discover how to choose the best belt-driven linear guide rail for load, speed, and precision needs. Expert tips included.

Are you searching for an efficient solution for ring spinning pick-and-place? The Auto Doffing Textile Spinning Machine is designed to meet your needs. It effectively replaces traditional labor-intensive pick-and-place operations in cotton ring spinning

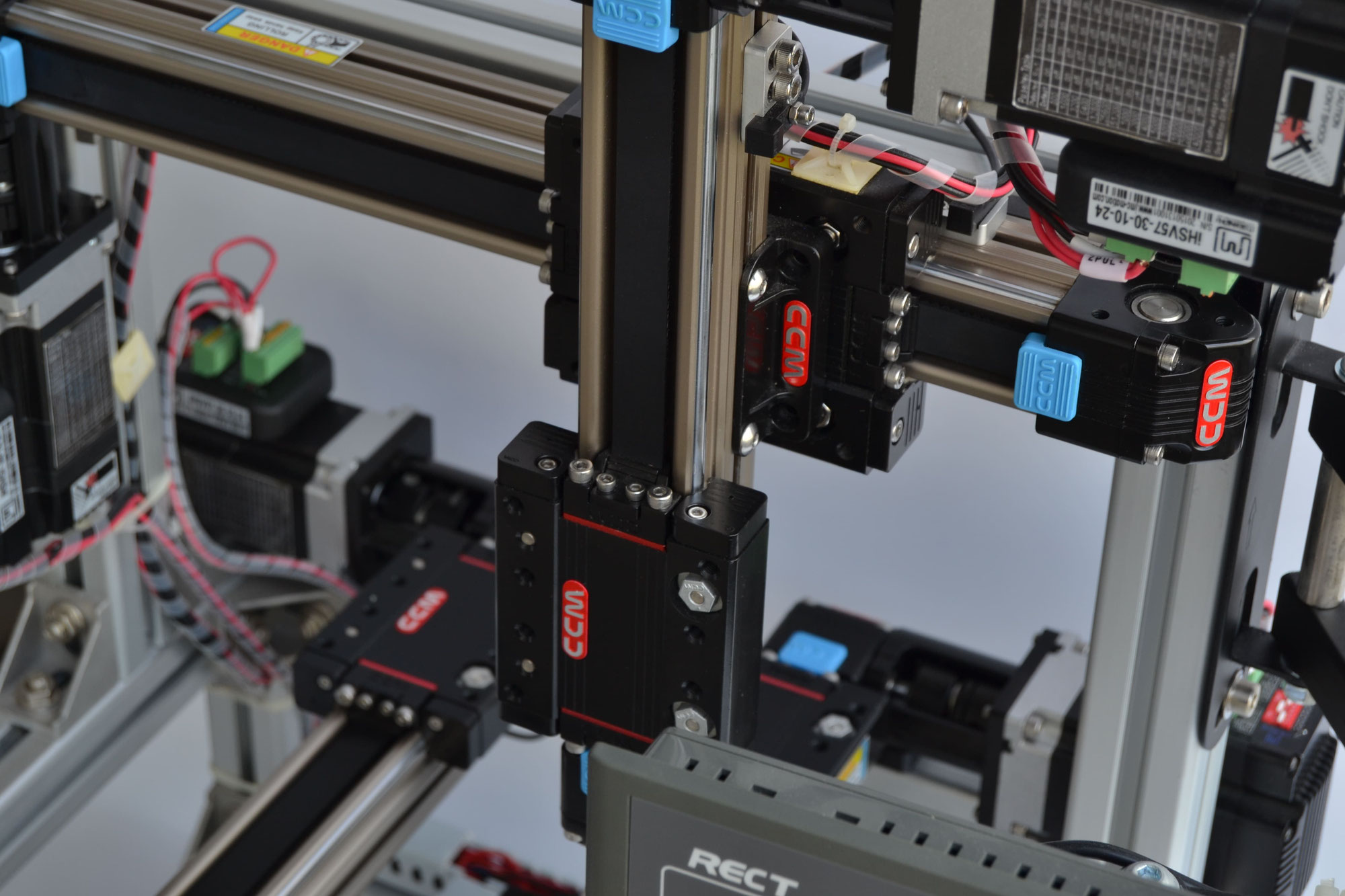

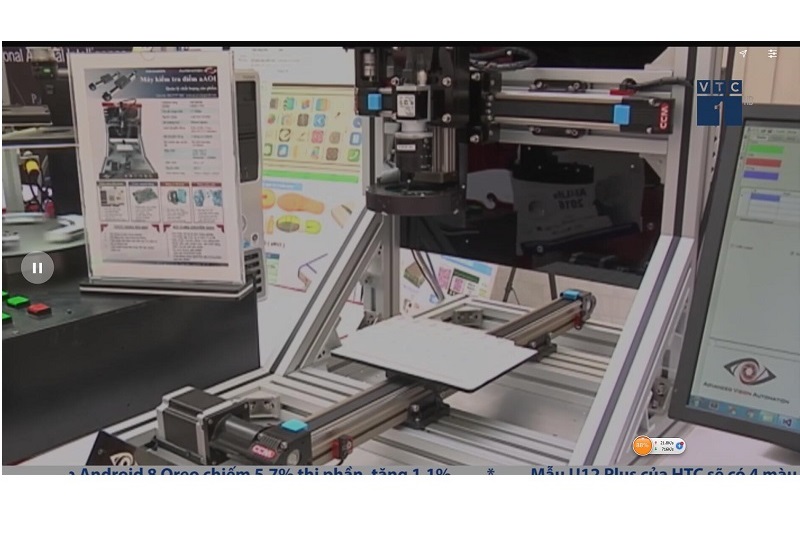

Learn how XYZ arm robots enhance precision and efficiency in optical vision inspection systems. Discover key benefits, applications, and how automation improves quality control in smart manufacturing environments.

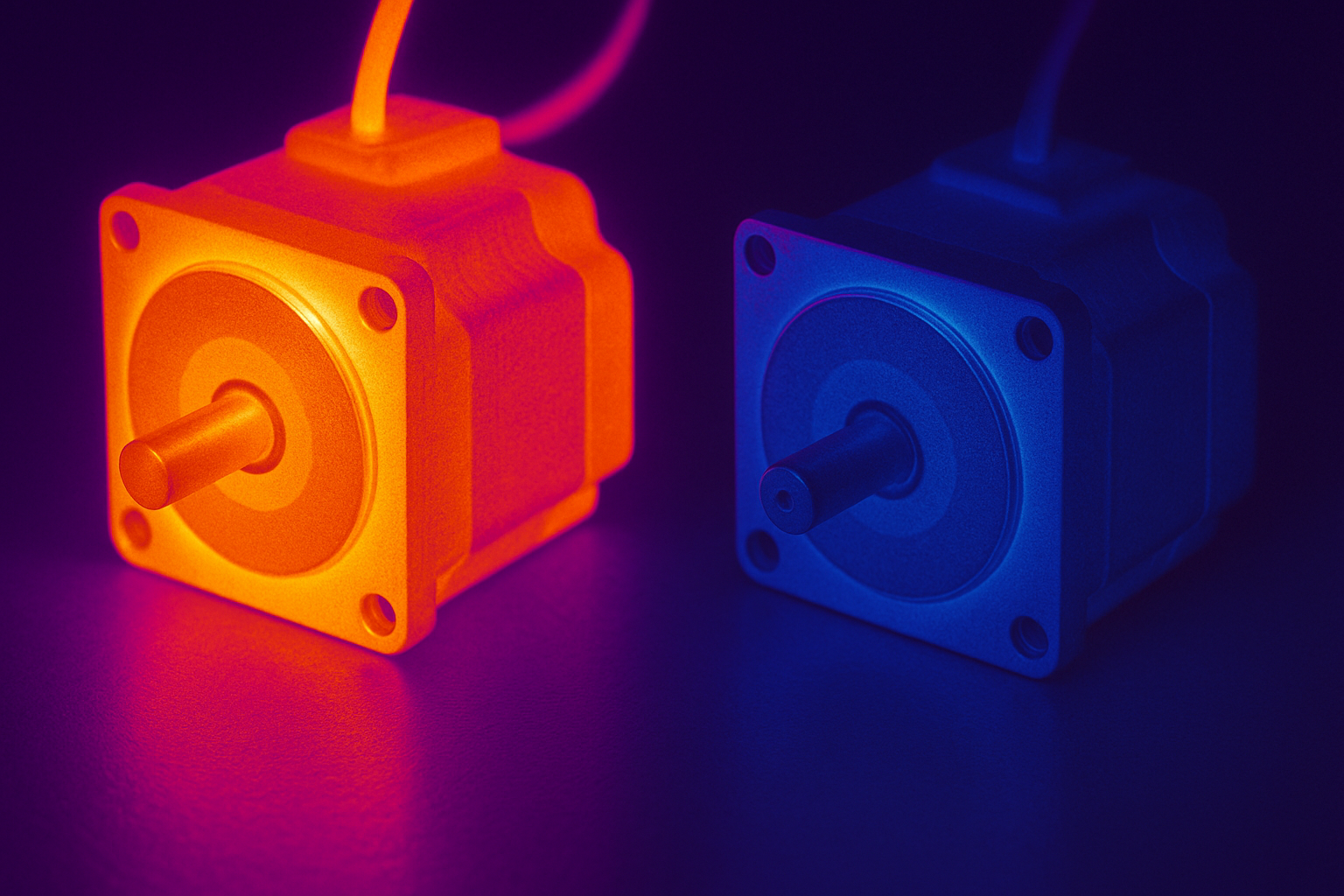

Is your stepper motor getting too hot? Learn the top reasons why stepper motors overheat and get expert-backed solutions to keep your system efficient, safe, and reliable.

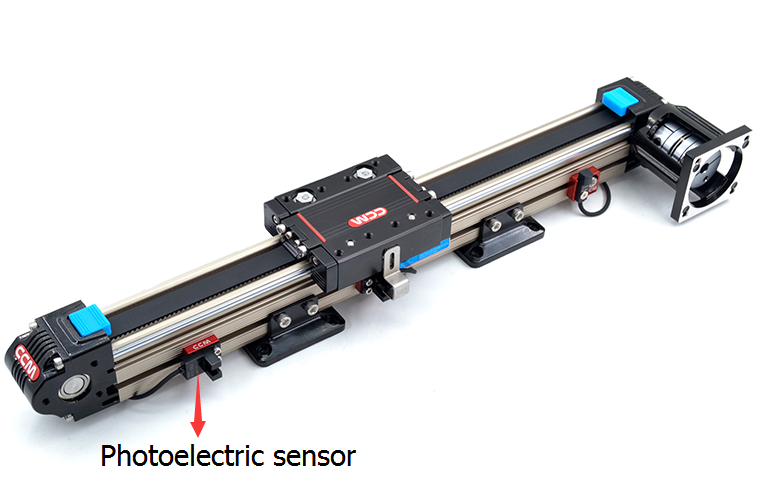

Learn the key differences between photoelectric and proximity sensors, their applications, pros and cons. Make smarter decisions for industrial automation, robotics, and detection systems

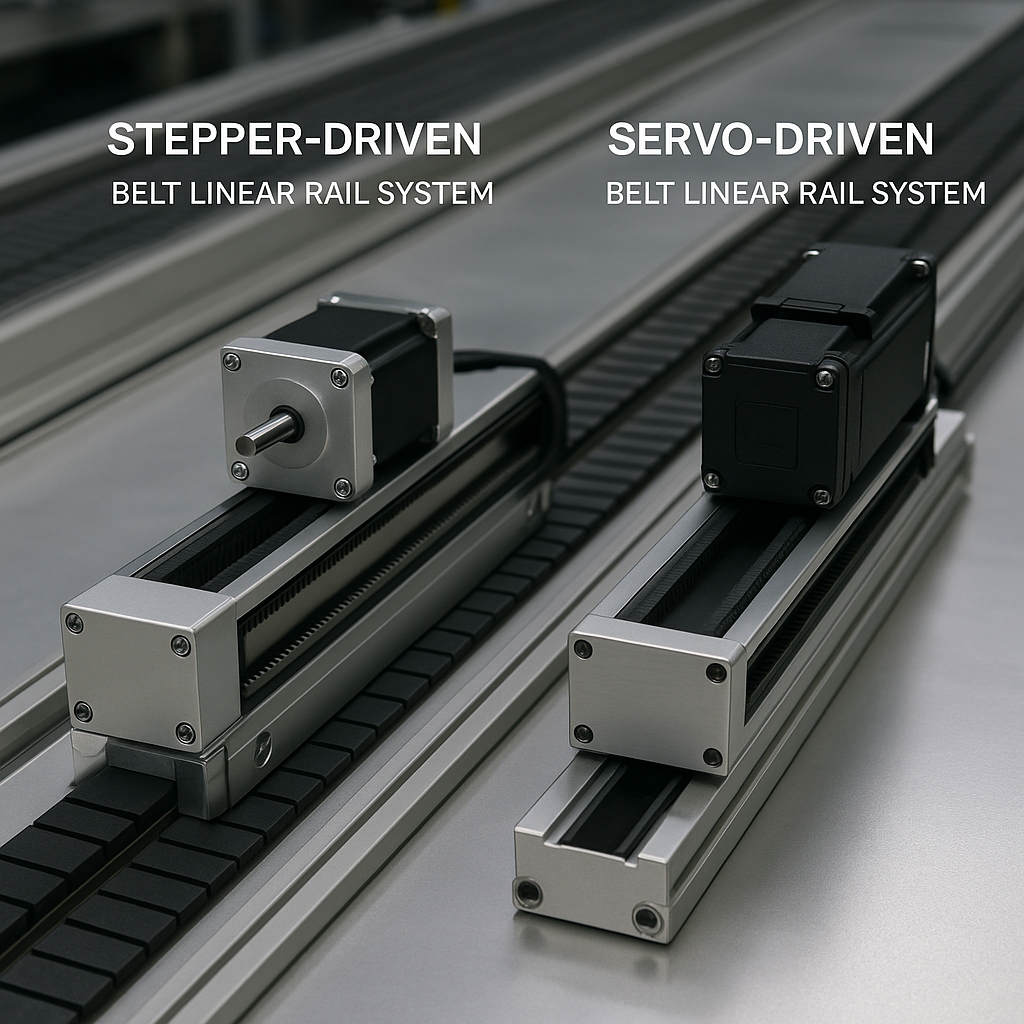

Discover how to choose between stepper and servo motors for your belt-driven linear motion system. This guide explains key differences in torque, speed, precision, and cost—ideal for automation, CNC, and industrial motion applications.

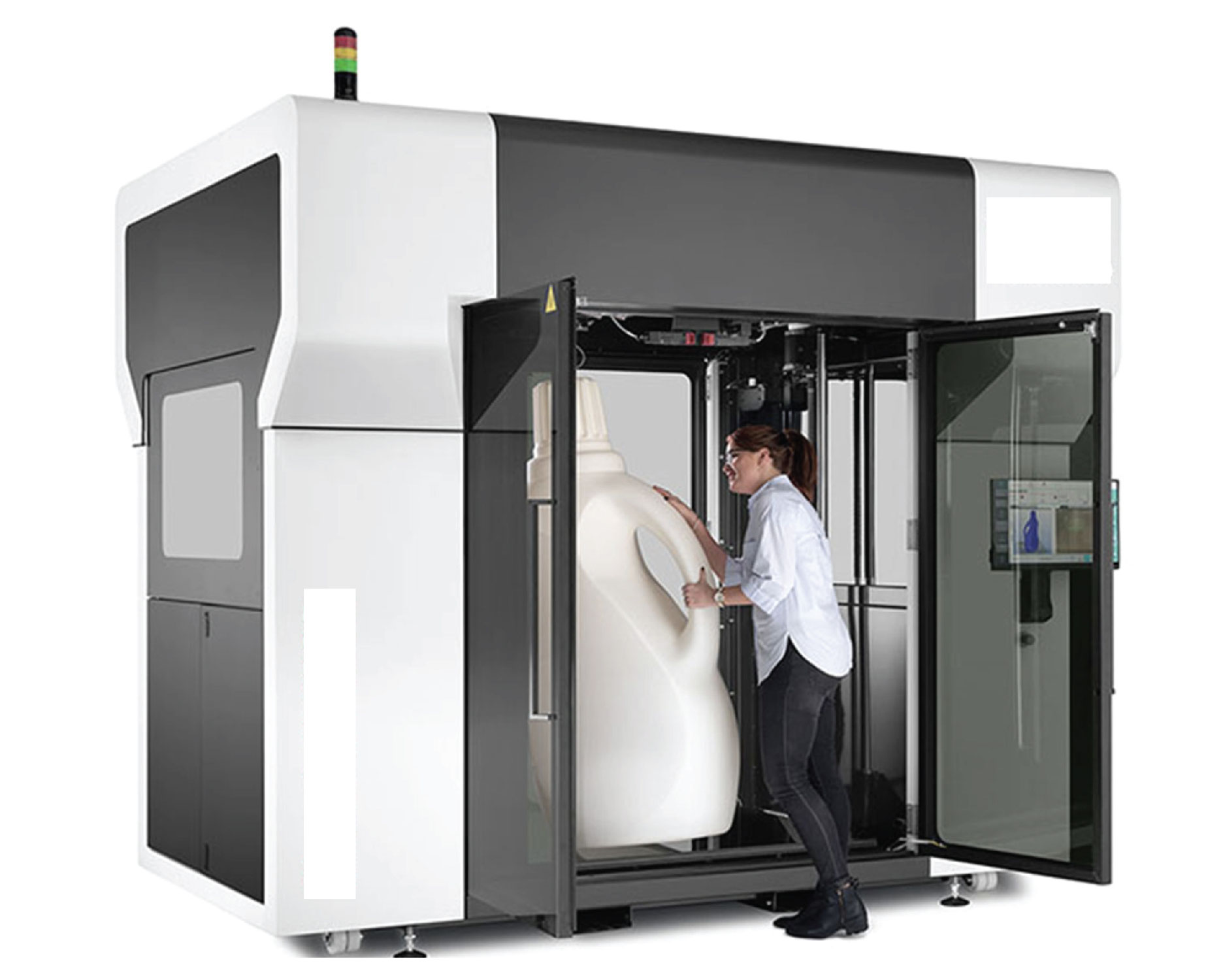

Learn how to choose the best linear guide rails for building high-precision 3D printers. Discover pros, cons, expert tips, and real-world examples for belt-driven and high-performance rail systems used by engineers and professional makers.