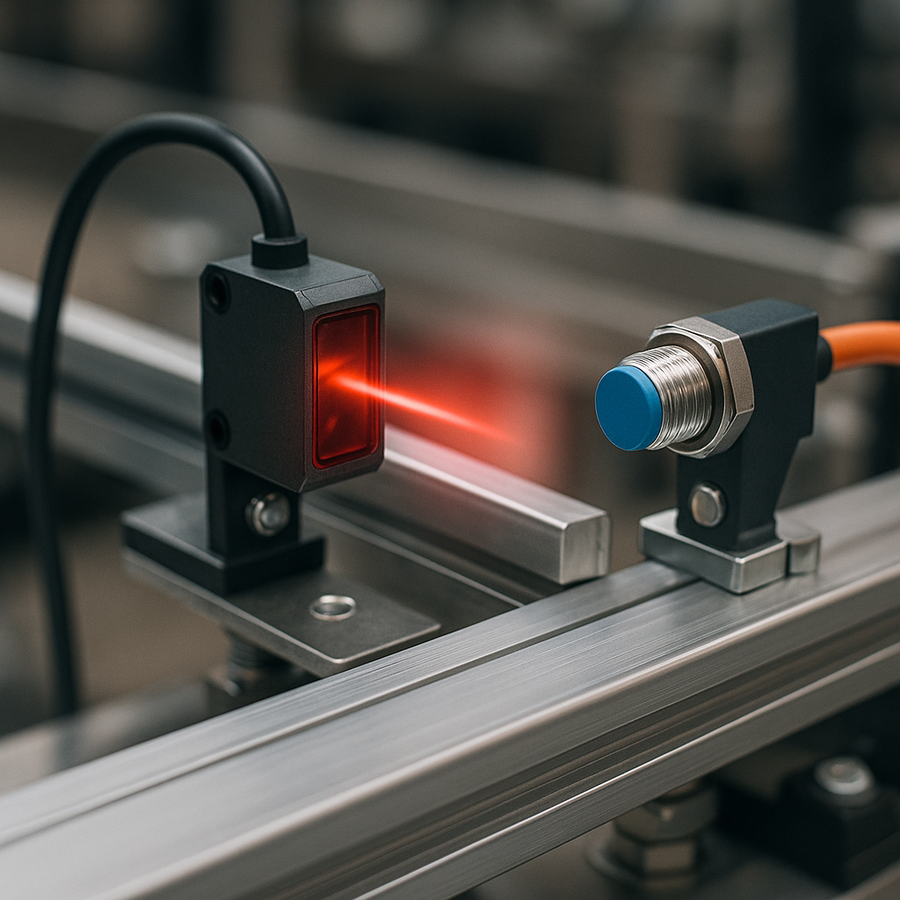

In the world of industrial automation and smart sensing, choosing the right type of sensor can greatly impact efficiency, reliability, and cost. Two of the most widely used sensor types are photoelectric sensors and proximity sensors.

Though they may serve similar detection purposes, these technologies differ in how they work, what environments they suit best, and how accurately they perform. Breaks down the differences, applications, advantages, and disadvantages of each to help engineers and integrators choose wisely.

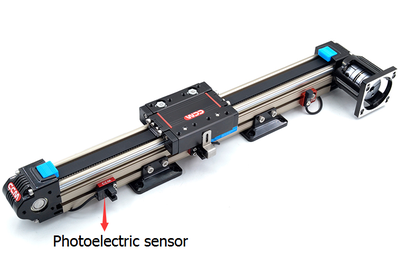

What Is a Photoelectric Sensor?

A photoelectric sensor detects the presence or absence of an object using a light beam (infrared or visible). It typically consists of:

-

Emitter: sends a beam of light

-

Receiver: detects light reflected or blocked by an object

🔧 Types of Photoelectric Sensors:

-

Through-beam: emitter and receiver are separate; detects when object interrupts beam

-

Retro-reflective: beam reflects off a mirror; object breaks beam to trigger detection

-

Diffuse reflective: emitter and receiver are combined; object reflects light back to the sensor

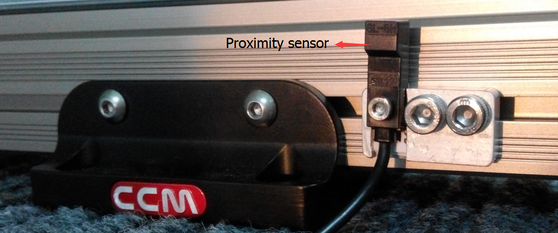

What Is a Proximity Sensor?

A proximity sensor detects objects without physical contact, using magnetic, capacitive, or inductive fields. It senses changes in its electromagnetic field when a target comes close.

🔧 Types of Proximity Sensors:

-

Inductive: for detecting metal objects only

-

Capacitive: for detecting metals, plastics, liquids, or powders

-

Magnetic: uses magnets and reed switches

-

Ultrasonic (sometimes considered proximity-type): detects using sound waves

Key Differences at a Glance

| Feature | Photoelectric Sensor | Proximity Sensor |

|

Sensing Method |

Light beam (IR or laser) |

Electromagnetic or capacitive fields |

|

Sensing Range |

Up to 10 meters (varies by type) |

Typically 1–50 mm (inductive), up to cm |

|

Object Material |

Any material (solid, clear, opaque) |

Inductive: metals, Capacitive: various |

|

Reaction Time |

Fast (microseconds) |

Fast, but varies slightly by type |

|

Environmental Sensitivity |

Affected by dust, dirt, or ambient light |

Affected by EMI, moisture, or temperature |

|

Mounting Complexity |

Requires alignment for beam |

Easier to install |

Common applications

Photoelectric Sensor Applications

-

Conveyor systems

-

Object counting

-

Packaging lines

-

Position detection on robotic arms

-

Transparent object detection (e.g., glass, plastic film)

Proximity Sensor Applications

-

Metal detection in CNC machines

-

Limit switches in automation

-

Level detection in hoppers/tanks (capacitive)

-

Gear speed monitoring

-

End-stop detection in 3D printers

Advantages & Disadvantages

Photoelectric Sensor

Pros:

-

Long sensing range

-

Works with nearly any material

-

Extremely fast response time

-

Compact designs available

Cons:

-

Affected by dust, smoke, and ambient light

-

Needs precise alignment

-

Reflective or transparent objects may need tuning

Proximity Sensor

Pros:

-

More resistant to contamination (dust, oil)

-

No need for optical alignment

-

Durable in harsh environments

-

Very reliable for short-range detection

Cons:

-

Limited sensing distance

-

Inductive only works with metals

-

Capacitive can be unstable in humid conditions

Which One Should You Use?

-

Choose a photoelectric sensor when you need longer sensing distances, flexible material detection, and fast reaction times—ideal for packaging lines, robotics, and assembly.

-

Choose a proximity sensor when working in dirty, industrial, or confined environments, or when you need reliable metal detection with minimal setup—perfect for CNC, machine tools, or position feedback.

Write a comment