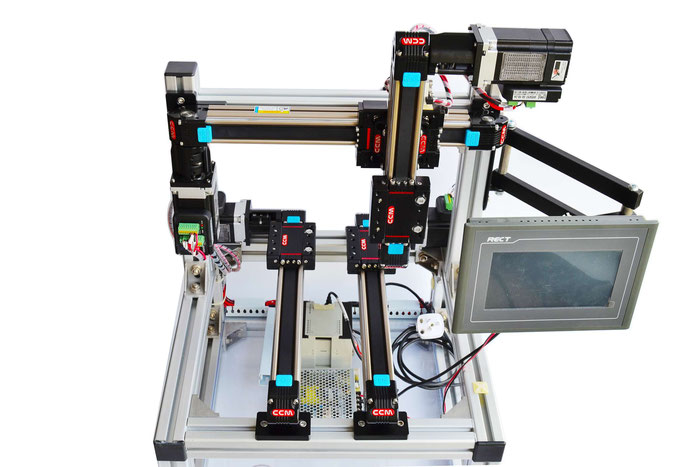

The XYZ Arm Robot: Revolutionizing Optical Vision Inspection Systems

In today’s fast-paced manufacturing world, precision, speed, and automation are key to maintaining competitive advantages. The XYZ arm robot has emerged as a game-changer in the optical vision inspection system (OVIS), providing a highly effective solution for automated inspection in industries such as electronics, automotive, and medical devices.

What is the XYZ Arm Robot?

The XYZ arm robot is a highly flexible robotic system capable of precise 3D motion. It is equipped with X, Y, and Z axis control, enabling it to move across three-dimensional space with incredible accuracy. This versatility makes it the perfect choice for integrating with optical vision inspection systems, where high precision and repeatability are critical.

How Does the XYZ Arm Robot Enhance Optical Vision Inspection?

The combination of an XYZ arm robot with an optical vision inspection system delivers a host of benefits that improve overall efficiency and product quality:

-

Precision and Accuracy: The XYZ arm’s movements are finely controlled, ensuring that cameras or sensors maintain optimal positioning to capture clear, accurate images of the objects being inspected.

-

Speed and Efficiency: The robot’s rapid and repeatable movements allow for faster inspection cycles, reducing bottlenecks in production lines.

-

Consistency: Unlike human inspectors, the XYZ arm operates with consistent precision, minimizing errors due to fatigue or distractions.

-

Automation and Integration: Integrating the XYZ arm with an OVIS enables fully automated quality control, eliminating the need for manual intervention and allowing for a more streamlined production process.

Applications in Optical Vision Inspection

From inspecting semiconductor components to printed circuit boards (PCBs), the XYZ arm robot is used to position cameras or sensors accurately for high-resolution image capture. These images are then analyzed to detect defects, irregularities, or deviations from specifications. The key areas where the XYZ arm is applied include:

-

Defect detection: Identifying scratches, cracks, or foreign particles on surfaces.

-

Dimension measurements: Ensuring that components meet strict dimensional tolerances.

-

Surface quality checks: Detecting uneven coatings, oxidation, or other surface imperfections.

Why Choose the XYZ Arm for Your OVIS?

The integration of the XYZ arm into an optical vision inspection system brings several compelling advantages:

-

Improved inspection accuracy: Achieves micron-level precision in positioning for optimal sensor alignment.

-

Faster inspection speeds: Ideal for high-throughput manufacturing environments.

-

Versatile functionality: Can be easily adapted to different inspection tasks by reprogramming or changing end-effectors.

Conclusion

By integrating the XYZ arm robot with an optical vision inspection system, manufacturers can significantly enhance their quality control processes. With its precision, speed, and versatility, this robotic solution ensures products meet the highest standards of quality, paving the way for greater automation and reduced human error in inspection processes.

For industries that demand the best in automation, the XYZ arm robot paired with optical vision inspection systems is the future of smart manufacturing.

Write a comment