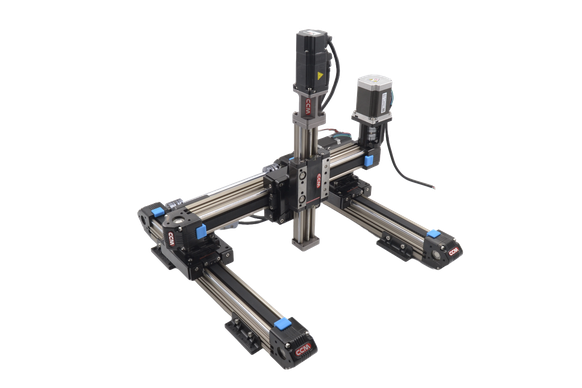

J45-20 linear guide rail for packing machines

Looking for the Right Linear Guide Rail for Your Application?

We understand how overwhelming it can be to choose the right linear guide rail when so many options online look similar and claim high performance. That’s why we’ve made it simple for you.

You have two clear options:

1. Stay here and check the technical specifications of our precision-engineered linear guide rail modules.

or check

2. How to Choose the Right Belt-Driven Linear Rail—Without Wasting Time or Money. Avoid common pitfalls, decode tech specs, and find the rail that fits your application perfectly.

Technical parameters of J45-20

-

Guide Width: 45 mm

-

Max Load: 20 kg

-

Pitch: 80 mm

-

Synchronous Wheel Spec: STD5M-16Z

-

Recommended Speed: ≤ 1.5 m/s

-

Customized Length: Up to 6 meters

-

Input Torque: ≤ 3 N·m

-

Belt Spec: PU-5M-15 (steel wire)

-

Straightness: 0.05 / 300 mm

-

Applicable Motors:

-

Stepper Motor: Nema 17 (Direct Connection)

-

Servo Motor: 100W (Direct Connection); 200W/400W (DC/Speed Reducer Set)

-

-

Suggested Length Adjustment: Effective stroke + 250 mm (length increments of 50 mm, such as 1000 mm, 1050 mm, 1100 mm)

This encapsulates the key parameters of the J45-20 linear motion module. If you require the full data sheet of the technical parameters, please contact us.

Features

-

High Precision – Engineered for accurate, repeatable motion in demanding applications.

-

Custom Lengths (up to 4 meters) – Tailored to fit your exact design and space requirements.

-

Corrosion-Resistant – Built with materials that withstand harsh environments and extend service life.

-

Maintenance-Free Operation – Designed for long-term use without regular servicing.

-

Ultra-Quiet Performance – Operates smoothly with minimal noise, ideal for sensitive settings.

-

Low Vibration – Ensures stable, consistent movement even at high speeds.

-

Trusted Reliability – Proven performance with minimal downtime across industries.

-

Long-Lasting Durability – Withstands continuous use under heavy loads and extended cycles.

-

Modular & Expandable – Easily integrates with accessories, sensors, and multi-axis systems.

Applications

-

Robotic Arms – Enables precise, repeatable linear motion for multi-axis automation.

-

3D Printers – Supports smooth, high-speed movement for accurate layer deposition.

-

CNC Router Machines – Ensures stable, rigid travel for cutting, milling, and shaping tasks.

-

Pick-and-Place Systems – Delivers fast, accurate positioning for high-throughput assembly lines.

-

Adhesive Dispensing Systems – Maintains controlled motion for uniform glue application.

-

Automated Painting Machines – Provides smooth, vibration-free movement for even coatings.

-

Packaging Equipment – Supports efficient and synchronized operations in automated packing lines.

-

Industrial Coding & Labeling Machines – Enables precise product marking and serialization.

-

Gantry Robots – Ideal for large-area, multi-axis systems requiring synchronized linear travel.

How to order

-

Tell Us About Your Project

Share your application details, goals, or challenges—our team is here to help. -

Provide Key Specs

Let us know the load weight, stroke length for each axis, travel speed, structure type, or environmental requirements. -

Receive a Tailored Quote

We’ll assess your needs and send you a detailed cost estimate—fast and accurate. -

Confirm & Start Production

Once payment is received, we’ll move your order into production with precision and care. -

We Handle the Shipping

We arrange safe and efficient delivery to your door, anywhere in the world.

-

Share Your Feedback

Your input matters—let us know how we did so we can keep improving.

How the Linear Guide Slider Belt-Driven System Improves Packaging Machines

How the Linear Guide Slider Belt-Driven System Improves Packaging Machines: Efficiency, Precision, and Reliability

In the fast-paced world of packaging, speed, precision, and reliability are paramount. Packaging machines must operate efficiently to meet high production demands while ensuring the quality and accuracy of every package. One technology that has significantly enhanced the performance of packaging machines is the linear guide slider belt-driven system. In this blog, we’ll explore how this system improves packaging operations, boosting efficiency, reducing maintenance, and ensuring smoother operations.

1. Precision Movement for Accurate Packaging

A key requirement for packaging machines is accurate movement, especially when positioning products, labeling, or sealing. Linear guide slider belt-driven systems provide high-precision motion, allowing packaging machines to position items accurately on the conveyor belt, align packaging materials, and execute precise labeling.

How It Benefits Packaging Machines:

The precision offered by these systems ensures that products are packaged correctly every time. Whether it’s placing a product in the correct position for sealing or aligning labels on bottles or

boxes, the linear guide slider belt-driven system ensures that every task is executed with pinpoint accuracy, reducing errors and improving

packaging quality.

2. Enhanced Speed and Throughput

In high-volume production environments, packaging machines must operate quickly and efficiently. Linear guide slider belt-driven systems allow for faster movement of components and products, improving the overall speed of the machine without sacrificing accuracy. These systems reduce friction, enabling smoother transitions along the conveyor, which leads to faster processing times.

How It Benefits Packaging Machines:

The improved speed and reduced friction offered by linear guide slider belt-driven systems increase throughput. Packaging lines can handle more

products per minute, allowing businesses to meet higher demand while maintaining consistency in the packaging process.

3. Reduced Maintenance Costs

Packaging machines can be expensive to maintain, especially in environments with high uptime demands. Linear guide slider belt-driven systems are designed for durability, with low friction and self-lubricating options available. This reduces wear and tear on components, decreasing the frequency of maintenance and extending the lifespan of the machine.

How It Benefits Packaging Machines:

Fewer maintenance requirements mean less downtime for repairs, which is especially important in industries where continuous operation is necessary. The long-lasting nature of linear guide slider belt-driven systems ensures that your packaging machines run smoothly without costly interruptions, allowing for higher productivity and lower

operational costs.

4. Smooth and Quiet Operation

The smooth operation of packaging machines is essential for creating a more comfortable work environment. Linear guide slider belt-driven systems operate with minimal noise and vibration, which can reduce wear on other machine components and minimize disruption in the production environment. These systems provide quiet, controlled movement, ensuring that packaging machines function smoothly without excessive noise.

How It Benefits Packaging Machines:

Quieter operation improves the overall work environment for employees and helps maintain the equipment’s longevity. Additionally, the reduced vibration minimizes the potential for misalignment

and wear on other machine components, ensuring that the entire packaging system remains reliable over time.

5. Increased Load Capacity

Packaging machines often need to handle a variety of product sizes and weights. Linear guide slider belt-driven systems are designed to accommodate heavier loads, ensuring that packaging machinery can move products of varying sizes and weights with ease. These systems are available in configurations that can support large-scale, heavy-duty applications without compromising performance.

How It Benefits Packaging Machines:

The ability to handle heavy loads means that linear guide slider belt-driven systems can be used in a wide range of packaging applications, from

small consumer goods to larger items like industrial equipment. This flexibility ensures that packaging machines can be used for a variety of products, maximizing the system’s utility and

adaptability.

6. Compact and Space-Saving Design

In many production facilities, space is at a premium, and packaging systems must be designed to fit within confined spaces. Linear guide slider belt-driven systems are compact and can be integrated into various machine configurations without taking up excessive space. Their compact design ensures that packaging machines are more efficient, especially in environments where space optimization is crucial.

How It Benefits Packaging Machines:

By utilizing a linear guide slider belt-driven system, packaging machines can operate in tighter spaces while still delivering high performance.

This is particularly beneficial in environments where floor space is limited, allowing manufacturers to maximize their operations without needing a larger footprint.

Conclusion:

The linear guide slider belt-driven system is a key technology that enhances the performance of packaging machines, making them faster, more precise, and more reliable. From improving speed and throughput to reducing maintenance costs and ensuring smooth operation, this system plays a vital role in optimizing packaging processes. By integrating linear guide slider belt-driven systems into your packaging machines, you can increase productivity, reduce downtime, and maintain consistent packaging quality.

Other Models

Accesories for linear guide rails