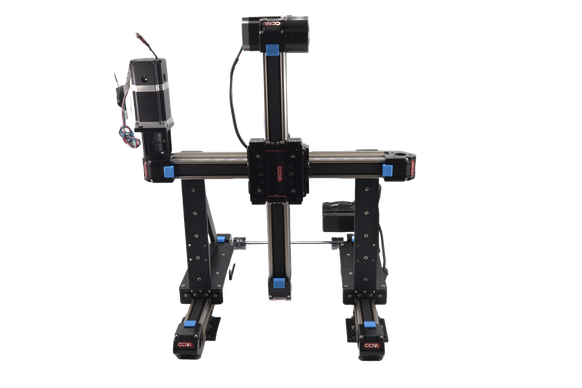

H60-40 Linear guide rail belt driven for XYZ motion axis

Looking for the Right Linear Guide Rail for Your Application?

We understand how overwhelming it can be to choose the right linear guide rail when so many options online look similar and claim high performance. That’s why we’ve made it simple for you.

You have two clear options:

1. Stay here and check the technical specifications of our precision-engineered linear guide rail modules.

or check

2. How to Choose the Right Belt-Driven Linear Rail—Without Wasting Time or Money. Avoid common pitfalls, decode tech specs, and find the rail that fits your application perfectly.

Technical parameters of H60-40

-

Guide Width: 60 mm

-

Max Load: 40 kg

-

Pitch: 95 mm

-

Synchronous Wheel Spec: STD5M-19Z

-

Recommended Speed: ≤ 2 m/s

-

Customized Length: Up to 6 meters

-

Input Torque: ≤ 8.5 N·m

-

Belt Spec: PU-5M-20 (steel wire)

-

Straightness: 0.05 / 300 mm

-

Applicable Motors:

-

Stepper Motor: 57/86 (DC/Speed Reducer Set)

-

Servo Motor: 750W (Direct Connection); 200W/400W (DC/Speed Reducer Set)

-

-

Suggested Length Adjustment: Effective stroke + 310 mm (in increments of 50 mm, such as 1000 mm, 1050 mm, 1100 mm)

This covers the essential details for the H60-40 linear motion module. If you require the full data sheet of the technical parameters, please contact us.

Features

-

High Precision – Engineered for accurate, repeatable motion in demanding applications.

-

Custom Lengths (up to 4 meters) – Tailored to fit your exact design and space requirements.

-

Corrosion-Resistant – Built with materials that withstand harsh environments and extend service life.

-

Maintenance-Free Operation – Designed for long-term use without regular servicing.

-

Ultra-Quiet Performance – Operates smoothly with minimal noise, ideal for sensitive settings.

-

Low Vibration – Ensures stable, consistent movement even at high speeds.

-

Trusted Reliability – Proven performance with minimal downtime across industries.

-

Long-Lasting Durability – Withstands continuous use under heavy loads and extended cycles.

-

Modular & Expandable – Easily integrates with accessories, sensors, and multi-axis systems.

Applications

-

Robotic Arms – Enables precise, repeatable linear motion for multi-axis automation.

-

3D Printers – Supports smooth, high-speed movement for accurate layer deposition.

-

CNC Router Machines – Ensures stable, rigid travel for cutting, milling, and shaping tasks.

-

Pick-and-Place Systems – Delivers fast, accurate positioning for high-throughput assembly lines.

-

Adhesive Dispensing Systems – Maintains controlled motion for uniform glue application.

-

Automated Painting Machines – Provides smooth, vibration-free movement for even coatings.

-

Packaging Equipment – Supports efficient and synchronized operations in automated packing lines.

-

Industrial Coding & Labeling Machines – Enables precise product marking and serialization.

-

Gantry Robots – Ideal for large-area, multi-axis systems requiring synchronized linear travel.

How to order

-

Tell Us About Your Project

Share your application details, goals, or challenges—our team is here to help. -

Provide Key Specs

Let us know the load weight, stroke length for each axis, travel speed, structure type, or environmental requirements. -

Receive a Tailored Quote

We’ll assess your needs and send you a detailed cost estimate—fast and accurate. -

Confirm & Start Production

Once payment is received, we’ll move your order into production with precision and care. -

We Handle the Shipping

We arrange safe and efficient delivery to your door, anywhere in the world.

-

Share Your Feedback

Your input matters—let us know how we did so we can keep improving.

🚫 What Not to Do When Building an XYZ Motion System

Avoid these costly mistakes and build a system that performs with precision.

XYZ motion systems are the backbone of Cartesian robots, CNC machines, 3D printers, and automation platforms. If you're building one, here are the top things you absolutely should not do:

1. ❌ Don’t Mix Mismatched Components

Using different rail types, incompatible motor drivers, or uneven mechanical tolerances causes sync issues and inconsistent motion.

🔧 Stick to compatible linear actuators, matching stepper drivers, and aligned mechanics across all axes for smooth, synchronized performance.

2. ❌ Don’t Skip Frame Alignment

If your frame isn’t square, your motion paths won’t be either.

🔧 Check diagonal measurements, squareness, and level before installing motion components. A crooked base creates long-term problems.

3. ❌ Don’t Ignore Load and Speed Requirements

Overloading small motors or using underbuilt rails leads to skipped steps, vibration, and rapid wear.

🔧 Calculate torque, speed, and load requirements for each axis and choose the right belt-driven or ball screw actuators accordingly.

4. ❌ Don’t Overcomplicate the Design

Adding unnecessary complexity makes the system harder to maintain and troubleshoot.

🔧 Keep it modular and accessible. Use off-the-shelf components where possible, and leave space for maintenance and upgrades.

5. ❌ Don’t Neglect Cable Management and Safety

Loose wiring, missing limit switches, or no emergency stop = recipe for disaster.

🔧 Use drag chains, label connections, and install safety features like e-stops, limit switches, and fuses. Your future self will thank you.

⚙️ Final Advice:

The best XYZ systems are simple, stable, and scalable. Focus on precision motion, solid structure, and smart design—and avoid shortcuts that cost more in the long run.

Need help choosing belt-driven actuators or designing a full XYZ setup? Let’s build it right, together.

Other Models

Accesories for linear guide rails