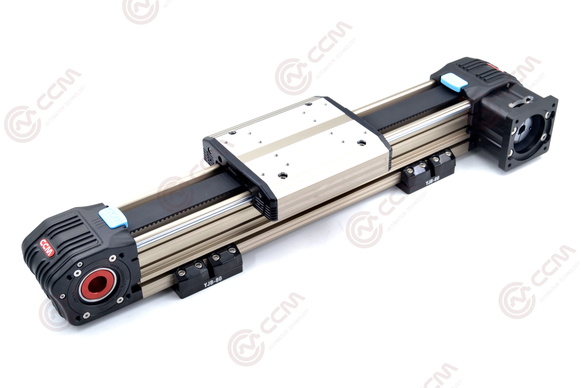

L50-30 Linear guide rail with motor on carriage for Food Processing Machines

Looking for the Right Linear Guide Rail for Your Application?

We understand how overwhelming it can be to choose the right linear guide rail when so many options online look similar and claim high performance. That’s why we’ve made it simple for you.

You have two clear options:

1. Stay here and check the technical specifications of our precision-engineered linear guide rail modules.

or check

2. How to Choose the Right Belt-Driven Linear Rail—Without Wasting Time or Money. Avoid common pitfalls, decode tech specs, and find the rail that fits your application perfectly.

Technical parameters of L50-30

-

Guide Width: 50 mm

-

Max Load: 30 kg

-

Pitch: 95 mm

-

Synchronous Wheel Spec: STD5M-19Z

-

Recommended Speed: ≤ 2 m/s

-

Customized Length: Up to 6 meters

-

Input Torque: ≤ 6.5 N·m

-

Belt Spec: PU-5M-20 (steel wire)

-

Straightness: 0.05 / 300 mm

-

Applicable Motors:

-

Stepper Motor: 57/86 (DC/Speed Reducer Set)

-

Servo Motor: 750W (Direct Connection); 200W/400W (DC/Speed Reducer Set)

-

-

Suggested Length Adjustment: Effective stroke + 320 mm (increments of 50 mm, such as 1000 mm, 1050 mm, 1100 mm)

This summary encapsulates the main technical parameters for the L50-30 linear motion system. If you require the full data sheet of the technical parameters, please contact us.

Features

-

High Precision – Engineered for accurate, repeatable motion in demanding applications.

-

Custom Lengths (up to 4 meters) – Tailored to fit your exact design and space requirements.

-

Corrosion-Resistant – Built with materials that withstand harsh environments and extend service life.

-

Maintenance-Free Operation – Designed for long-term use without regular servicing.

-

Ultra-Quiet Performance – Operates smoothly with minimal noise, ideal for sensitive settings.

-

Low Vibration – Ensures stable, consistent movement even at high speeds.

-

Trusted Reliability – Proven performance with minimal downtime across industries.

-

Long-Lasting Durability – Withstands continuous use under heavy loads and extended cycles.

-

Modular & Expandable – Easily integrates with accessories, sensors, and multi-axis systems.

Applications

-

Robotic Arms – Enables precise, repeatable linear motion for multi-axis automation.

-

3D Printers – Supports smooth, high-speed movement for accurate layer deposition.

-

CNC Router Machines – Ensures stable, rigid travel for cutting, milling, and shaping tasks.

-

Pick-and-Place Systems – Delivers fast, accurate positioning for high-throughput assembly lines.

-

Adhesive Dispensing Systems – Maintains controlled motion for uniform glue application.

-

Automated Painting Machines – Provides smooth, vibration-free movement for even coatings.

-

Packaging Equipment – Supports efficient and synchronized operations in automated packing lines.

-

Industrial Coding & Labeling Machines – Enables precise product marking and serialization.

-

Gantry Robots – Ideal for large-area, multi-axis systems requiring synchronized linear travel.

How to order

-

Tell Us About Your Project

Share your application details, goals, or challenges—our team is here to help. -

Provide Key Specs

Let us know the load weight, stroke length for each axis, travel speed, structure type, or environmental requirements. -

Receive a Tailored Quote

We’ll assess your needs and send you a detailed cost estimate—fast and accurate. -

Confirm & Start Production

Once payment is received, we’ll move your order into production with precision and care. -

We Handle the Shipping

We arrange safe and efficient delivery to your door, anywhere in the world.

-

Share Your Feedback

Your input matters—let us know how we did so we can keep improving.

Enhance Efficiency and Hygiene with Our Precision Linear Guide Rails

Enhancing Efficiency and Hygiene: The Advantages of Our Linear Guide Rails in Critical Environments

In industries where hygiene standards are paramount, such as food processing, pharmaceuticals, and medical device manufacturing, precision, reliability, and cleanliness are non-negotiable. Linear guide rails are at the heart of many automated systems, and when designed with hygiene in mind, they can enhance efficiency while maintaining the highest hygiene standards.

1. Superior Precision and Reliability

Our linear guide rails are designed for precision and consistent performance. In industries where even a small deviation can cause issues, such as automated assembly or sorting of sterile products, the accuracy of our rails ensures that machinery operates smoothly and consistently. With tight tolerances and minimal play, our rails provide the reliability needed to maintain high production standards.

How It Enhances Hygiene:

Accurate movement minimizes the risk of contamination. By ensuring that parts and products are handled properly and without delay, the chances of exposure to dirt or contaminants are

significantly reduced.

2. Easy to Clean and Maintain

Hygiene is a critical consideration in environments like food production or pharmaceutical packaging, where strict sanitation protocols must be followed. Our linear guide rails are built with smooth, easy-to-clean surfaces that prevent the accumulation of dirt, bacteria, and debris. These rails are designed to be resistant to harsh cleaning chemicals and sanitizing agents, ensuring that regular maintenance doesn’t impact the functionality or cleanliness of your system.

How It Enhances Hygiene:

Our rails are engineered for easy disinfection and cleaning, with no complex joints or hard-to-reach areas where contaminants could hide. This makes it easier to adhere to sanitation standards,

saving both time and resources in cleaning procedures.

3. Corrosion Resistance for Harsh Environments

In industries like food processing, the presence of moisture, oils, and cleaning agents can cause corrosion if equipment isn’t properly engineered. Our linear guide rails are constructed with corrosion-resistant materials, making them perfect for environments where cleanliness and long-term durability are critical. They are designed to withstand high-pressure washes, chemical treatments, and mid-high humidity without losing performance.

How It Enhances Hygiene:

Corrosion-resistant materials prevent the growth of mold, rust, and other contaminants that could compromise hygiene. By preventing degradation over time, our rails ensure that the production

line remains compliant with hygiene regulations and avoids contamination risks.

4. Minimal Friction and Low Maintenance

The low-friction design of our linear guide rails ensures smooth and efficient operation with minimal wear and tear. This not only extends the lifespan of your equipment but also reduces the need for frequent maintenance or repairs, which can disrupt production. Low maintenance means less downtime for cleaning, keeping your processes running smoothly and hygienically.

How It Enhances Hygiene:

Reduced friction means fewer particles are shed from the components, reducing the likelihood of contaminants entering the production area. This helps maintain a clean and safe working environment

while ensuring optimal system performance.

5. Flexibility for Custom Applications

Our linear guide rails are highly customizable to suit a variety of applications, including those in industries that require strict hygiene standards. Whether you need to accommodate a specific load capacity, speed, or special materials, we can design linear guide rails tailored to your unique needs.

How It Enhances Hygiene:

Custom designs can accommodate the unique layout and operational requirements of your facility, ensuring that the system supports both efficiency and cleanliness. We can integrate features that

make the system even more suitable for sterile environments, such as seamless construction and additional protection against contamination.

6. High Durability in Demanding Conditions

Our linear guide rails are built to perform under demanding conditions without compromising on hygiene. Whether operating in medium-high temperatures, exposed to cleaning agents, or enduring constant movement, these rails are designed for high durability, ensuring long-term efficiency without sacrificing hygiene standards.

How It Enhances Hygiene:

Durability means fewer replacements and repairs, reducing the potential for contamination during maintenance activities. Additionally, our rails are engineered to withstand repeated cleaning

cycles without degrading, ensuring continuous compliance with hygiene regulations.

Conclusion:

In industries where hygiene is a top priority, our linear guide rails offer the perfect balance of efficiency, reliability, and cleanliness. With precision engineering, easy cleaning, corrosion resistance, and minimal friction, our rails enhance your processes without affecting the high hygiene standards that are essential in sectors like food, pharmaceuticals, and medical device manufacturing.

By choosing our linear guide rails, you ensure that your systems operate at their best, all while maintaining the highest levels of hygiene and safety. Trust in the reliability and performance of our rails to keep your operations running smoothly and hygienically.

Other Models

Accesories for linear guide rails