CCM W40-10 linear guide rails belt drive in AOI systems

Looking for the Right Linear Guide Rail for Your Application?

We understand how overwhelming it can be to choose the right linear guide rail when so many options online look similar and claim high performance. That’s why we’ve made it simple for you.

You have two clear options:

1. Stay here and check the technical specifications of our precision-engineered linear guide rail modules.

or check

2. How to Choose the Right Belt-Driven Linear Rail—Without Wasting Time or Money. Avoid common pitfalls, decode tech specs, and find the rail that fits your application perfectly.

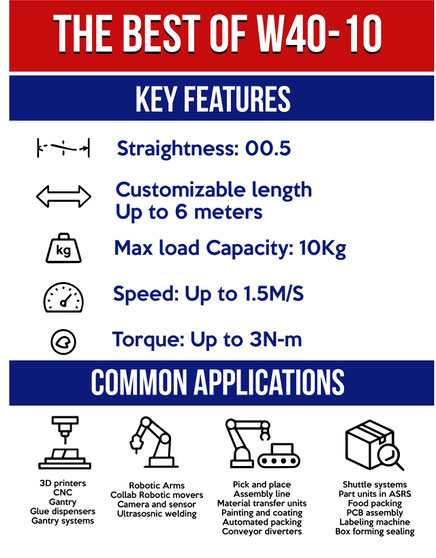

Technical parameters W40-10

-

Guide Width: 40 mm

-

Max Load: 10 kg

-

Pitch: 75 mm

-

Synchronous Wheel Spec: HTD3M-25Z

-

Recommended Speed: ≤ 1.5 m/s

-

Customized Length: Up to 6 meters

-

Input Torque: ≤ 3 N·m

-

Belt Spec: PU-3M-15 (steel wire)

-

Straightness: 0.05 / 300 mm

-

Applicable Motors:

-

Stepper Motor: Nema 17 (Direct Connection)

-

Servo Motor: 100W (Direct Connection); 200W/400W (DC/Speed Reducer Set)

-

-

Suggested Length Adjustment: Effective stroke + 250 mm, with increments of 50 mm (e.g., 1000 mm, 1050 mm, 1100 mm)

This information encapsulates the key technical details for the W40-10 linear motion module. If you require the full data sheet of the technical parameters, please contact us.

Features

-

High Precision – Engineered for accurate, repeatable motion in demanding applications.

-

Custom Lengths (up to 4 meters) – Tailored to fit your exact design and space requirements.

-

Corrosion-Resistant – Built with materials that withstand harsh environments and extend service life.

-

Maintenance-Free Operation – Designed for long-term use without regular servicing.

-

Ultra-Quiet Performance – Operates smoothly with minimal noise, ideal for sensitive settings.

-

Low Vibration – Ensures stable, consistent movement even at high speeds.

-

Trusted Reliability – Proven performance with minimal downtime across industries.

-

Long-Lasting Durability – Withstands continuous use under heavy loads and extended cycles.

-

Modular & Expandable – Easily integrates with accessories, sensors, and multi-axis systems.

Applications

-

Robotic Arms – Enables precise, repeatable linear motion for multi-axis automation.

-

3D Printers – Supports smooth, high-speed movement for accurate layer deposition.

-

CNC Router Machines – Ensures stable, rigid travel for cutting, milling, and shaping tasks.

-

Pick-and-Place Systems – Delivers fast, accurate positioning for high-throughput assembly lines.

-

Adhesive Dispensing Systems – Maintains controlled motion for uniform glue application.

-

Automated Painting Machines – Provides smooth, vibration-free movement for even coatings.

-

Packaging Equipment – Supports efficient and synchronized operations in automated packing lines.

-

Industrial Coding & Labeling Machines – Enables precise product marking and serialization.

-

Gantry Robots – Ideal for large-area, multi-axis systems requiring synchronized linear travel.

How to order

-

Tell Us About Your Project

Share your application details, goals, or challenges—our team is here to help. -

Provide Key Specs

Let us know the load weight, stroke length for each axis, travel speed, structure type, or environmental requirements. -

Receive a Tailored Quote

We’ll assess your needs and send you a detailed cost estimate—fast and accurate. -

Confirm & Start Production

Once payment is received, we’ll move your order into production with precision and care. -

We Handle the Shipping

We arrange safe and efficient delivery to your door, anywhere in the world.

-

Share Your Feedback

Your input matters—let us know how we did so we can keep improving.

Top 5 Things You Really Need to Know Before Building Your AIO System

Thinking about building an All-in-One (AIO) system? Great move. These systems can save you time, space, and money—if you build them right from the start. Before you dive in, here are five key things we’ve learned (the hard way) that can help you get it right the first time.

1. Know Exactly What You’re Building

This might sound obvious, but trust us—start by being crystal clear on what your AIO system actually needs to do. Is it automating a process? Collecting data? Controlling other machines? Once you lock down the goal, everything else—hardware, motion, layout—gets way easier to figure out.

2. Use Smart, Space-Saving Hardware (Yes, This Includes Our Actuators 😉)

With AIO systems, space is always tight. That’s why every component you choose needs to do more with less. A solid processor is important, sure—but let’s talk about what really makes these systems move: belt-driven linear guide rail actuators.

If your AIO setup needs to slide, pick, place, push, or pull anything, you’ll need precision motion—and that’s where our actuators come in. They’re compact, fast, and built to run smooth in woking industrial schedules, even in tight enclosures. We use sealed bearings, hardened rails, and high-quality belts, so you don’t have to worry about downtime or wear.

We build these like we’re going to install them in our own machines. Because we know the importance of each project.

3. Think Long-Term: Leave Room for Growth

Tech changes fast. So build your AIO system like a Lego set—easy to add on, swap out, or upgrade later. Our linear actuators are modular, too. You can replace them easily for a longer version at any time, with our mounting accessories, reconfigure them, or integrate them with whatever comes next. No drama, no starting from scratch.

4. Keep It Cool (Literally)

AIO machines can heat up fast, especially when everything’s packed in tight. That’s why airflow and material choice matter. Our actuators are designed with low-friction, high-durability materials so they don’t add to your thermal headache. Bonus: they’re low noise too, so your system runs quiet.

5. Keep It Safe, Keep It Running

When you’ve got one machine doing it all, a single failure can mess up everything. So yeah, secure your system—and monitor it. Our actuators can include feedback options like encoders, so you can track position, detect issues early, and keep things running like clockwork.

Bottom line?

We don’t just sell actuators—we build motion systems with you. If you ever get stuck, or need help choosing the right size, speed, or setup, reach out. We’re engineers, too. And we’re here to help.

Want us to help you plan your next AIO system or pick the perfect actuator? Let’s talk. Click here to contact us

Other Models

Accesories for linear guide rails