A Gantry Robot Machine System is a type of automation system where a robotic arm or a tool moves along a set of rails, typically mounted on an overhead structure. This design allows the system to have full control over the motion along multiple axes, often X, Y, and Z, and is commonly used in applications requiring high precision and heavy lifting capabilities, such as material handling, CNC machining, and 3D printing. CCM belt driven linear actuators are widely used in gantry system from electronic assembly and electronic manufacturing to vision systems and industrial automation.

Gantry robots are also called Cartesian or linear robots.

They are usually large systems built with linear guide rail that perform pick and place applications, but they can also be used in welding and other applications.

What Is a Gantry Robot?

A gantry robot is a type of industrial robot system that moves linearly along X, Y, and Z axes using a rigid mechanical frame — typically constructed from aluminum or steel profiles.

Also called a Cartesian robot, it operates with a rectangular work envelope, allowing precise motion in straight lines rather than arcs.

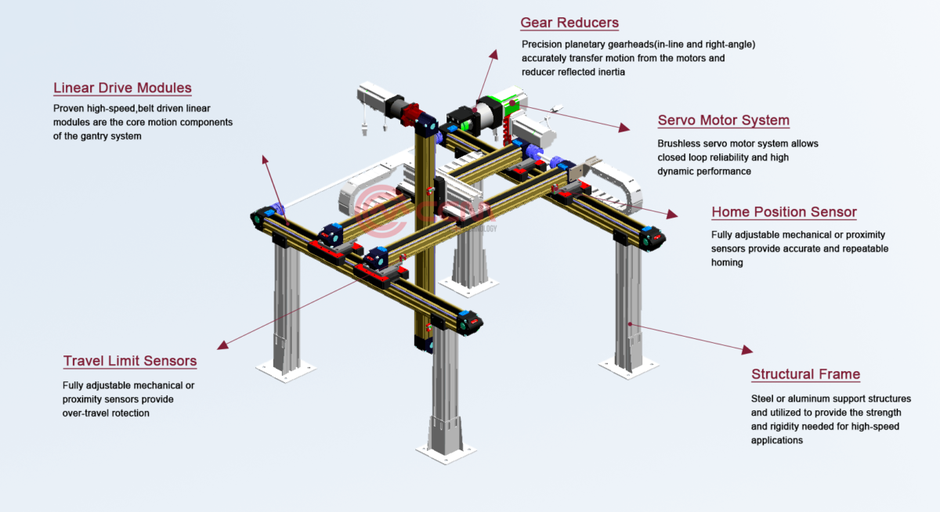

Structure and Main Components

A typical gantry robot includes:

1. Linear Guide Rails / Actuators

-

Provide motion along each axis (X, Y, Z)

-

Can be belt-driven, ball screw, or rack & pinion based

2. Carriages

-

Move along each axis, holding the payload, tool, or end-effector

3. Frame/Base

-

Rigid aluminum or steel structure providing mechanical stability

4. Motors & Drives

-

Typically stepper or servo motors controlling motion with high accuracy

5. Controllers

-

Control system sending precise movement instructions (PLC, PC, or embedded)

6. Sensors

-

End-stop, position feedback, or collision detection sensors.

Advantages of Gantry Robots

| Advantages | Why It Matters |

| Large Working Area | Ideal for wide conveyors, large objects, or multiple stations |

| High Precision and Repeatability | Critical for inspection and assembly |

| Modular and Scalable | Easy to adapt or expand by adding axes or modules |

| Simple Programming | Cartesian movement is intuitive and easy to control |

| Lower Cost Than Articulated Arms | Especially for large areas applications |

Limitations to Consider

-

❌ Bulky structure – requires more floor space

-

❌ Slower than SCARA/Articulated robots for complex curves

-

❌ External cabling and wire routing can become complex

🔍 But for tasks needing accuracy, repeatability, and structure — it’s hard to beat.

🧠 Final Thoughts: Is a Gantry Robot Right for You?

If your application involves structured movements, long linear strokes, or needs to span large areas with minimal cost, a gantry robot is one of the smartest solutions available.

Whether you're automating a production line, building a custom machine, or integrating a robotic inspection station, gantry systems offer the flexibility and precision modern industries demand.

Need a custom gantry solution?

Our engineers can help you configure a fully tailored system — from the frame to the motor.

👉 Contact our technical team now

🛒 Looking for pre-assembled gantry robots or linear modules?

Visit our Customizable products to browse our most popular systems.

Accesories for linear guide rails