In modern automation and machine design, selecting the right linear motion solution can make or break your project's performance. Among various options, belt-driven linear guide rails stand out for their blend of speed, travel range, and cost-effectiveness.

We'll break down what a belt-driven linear guide rail is, why engineers choose it, and how to integrate one into your system.

Why Choose a Belt-Driven Linear Guide Rail?

If your application demands medium to long travel distances with moderate loads and you value high speed and lower costs, a belt-driven system could be ideal.

Unlike ball-screw drives optimized for heavy loads and high precision over shorter spans, belt-driven guides excel in scenarios like pick-and-place gantries, conveyor positioning, and large-format 3D printing.

How It Works

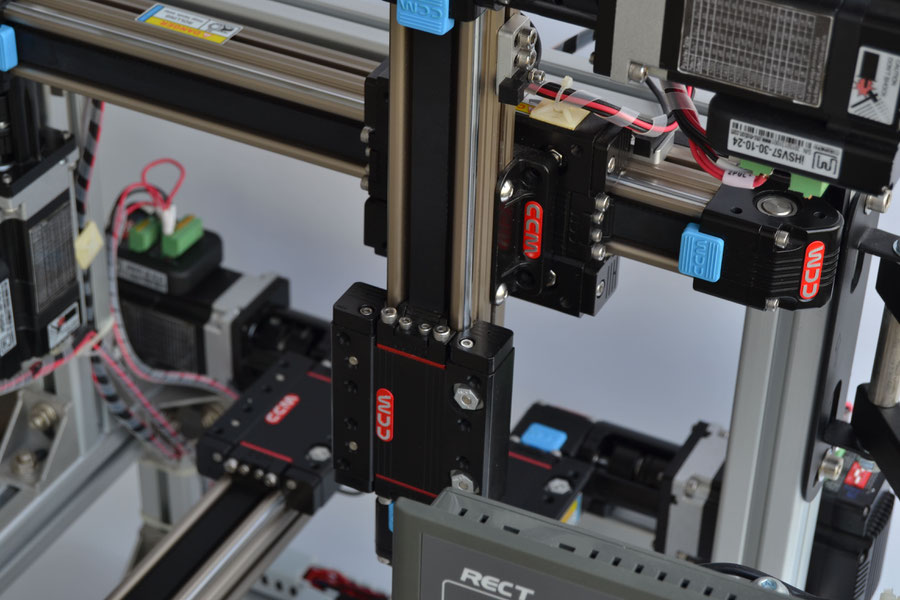

A typical belt-driven linear guide rail comprises:

- Rail and Carriage: The carriage rides on the rail using linear bearings or rollers for smooth motion.

- Belt: Made from reinforced polyurethane or rubber, the belt loops around pulleys at each end of the rail.

- Pulleys & Tensioner: End pulleys guide the belt; a tensioner maintains optimal belt tension to minimize stretch.

- Drive Motor: Coupled to one pulley (or via an external gearbox), the motor drives the belt, moving the carriage.

As the motor rotates, the belt translates rotary motion into linear movement, carrying the carriage along the rail.

Key factors include belt material, width, tension, pulley diameter, and carriage design, all influencing performance.

Key Adventages

High Speed & Long Travel: Capable of rapid movements over meters of travel, ideal for large work envelopes.

Cost-Effective for Extended Lengths: More affordable than ball screws or rack & pinion for long distances.

Low Noise & Smooth Operation: Belt systems typically run quieter and with less vibration.

Lightweight Moving Mass: Belt and carriage setups often weigh less than equivalent screw drives, aiding acceleration.

Easier Replacement & Maintenance: Swapping out a worn belt is simpler than refurbishing a leadscrew.

Potential Drawbacks

Moderate Precision: Belt stretch and elasticity limit positional accuracy compared to ball-screw systems.

Load Limitations: Suited for light to moderate loads; very heavy payloads may require alternative drives.

Periodic Maintenance: Belts wear over time, needing periodic tension checks and replacements.

If you want more info about how to maintenances, check this info: Top 5 Maintenance Tips For Linear Actuator Guide Rail Belt Driven Slider

Environmental Sensitivity: Extreme temperatures or chemical exposure can degrade belt materials.

Pros & Cons Summary

Pros:

- High Speed & Long Travel

- Cost-Effective for Extended Lengths

- Low Noise & Smooth Operation

- Lightweight Moving Mass

- Easier Replacement & Maintenance

Cons:

- Moderate Precision

- Load Limitations

- Periodic Maintenance

- Environmental Sensitivity

Common Applications

- Pick-and-place gantries in assembly lines

- Large-format 3D printers and CNC machines with extended travel

- Conveyor indexing and positioning systems

- Automated storage and retrieval systems (medium loads)

- Packaging machinery requiring fast shuttle movements

Frequent Questions.

Q: How long can last a ccm linear guide rail belt driven?

A: Our linear guide rails can work for more than 100.000 Hours with a minimun maintenance. Changing the belt and adding oil time to time.

Q: How accurate is a belt-driven linear guide rail?

A: Typical positional accuracy ranges from ±0.1 mm to ±0.5 mm, depending on belt quality, tensioning, and system rigidity.

Q: What maintenance routines are essential?

A: Regularly inspect belt wear, check tension per manufacturer specs, verify pulley alignment, and replace belts proactively.

Q: Can I achieve high acceleration?

A: Yes, due to lower moving mass, belt systems can deliver high acceleration, but ensure motor and controller are sized appropriately.

Q: What travel lengths are feasible?

A: In CCM Automation Lengths From 1 meter to 6 meters or more are common; beyond that, consider belt stretch effects and structural support to prevent deflection.

Q: Are there variations in belt materials?

A: Yes—materials like polyurethane with steel or Kevlar reinforcement are common; We help you to select based on load, speed, and environmental needs.

More Information

Contact our engineering team: to size a belt-driven solution for your application.

Other information that enriches your knowlage:

- When should I consider a belt-driven system vs. alternatives?

- What load capacities can belt-driven guides handle?

- How do I determine required speed and acceleration?

- How does accuracy and repeatability compare?

- What belt types and materials are available?

- How to calculate belt tension and its importance?

- What drive motors work best with belt-driven systems?

- What environmental factors affect selection?

- What maintenance practices are needed?

- What are common failure modes and how to prevent them?

- How to evaluate cost vs. ROI?

- How to choose a supplier or manufacturer?

- Can belt-driven systems scale for large travel spans?

Write a comment