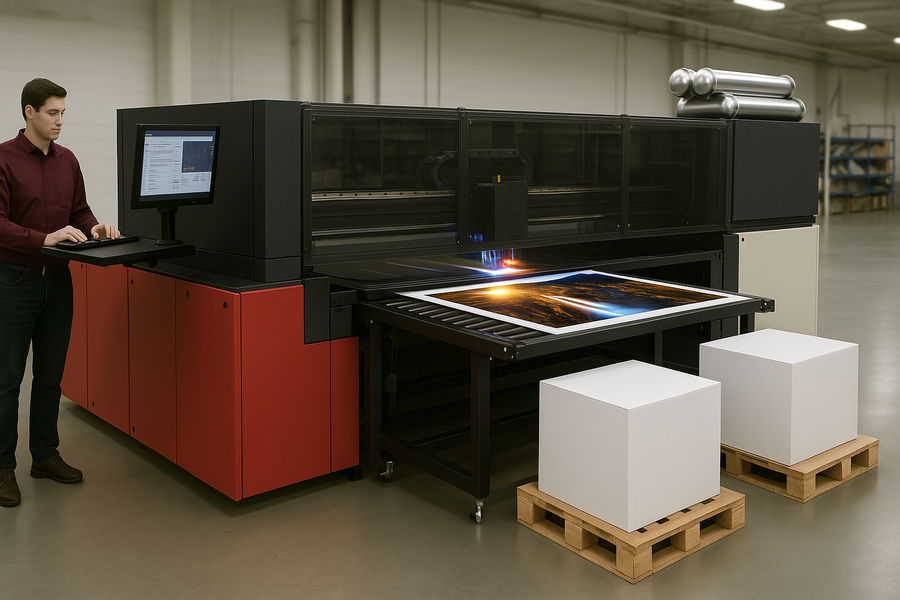

H80-50 Linear guide rails belt driven for inkjet printers

Looking for the Right Linear Guide Rail for Your Application?

We understand how overwhelming it can be to choose the right linear guide rail when so many options online look similar and claim high performance. That’s why we’ve made it simple for you.

You have two clear options:

1. Stay here and check the technical specifications of our precision-engineered linear guide rail modules.

or check

2. How to Choose the Right Belt-Driven Linear Rail—Without Wasting Time or Money. Avoid common pitfalls, decode tech specs, and find the rail that fits your application perfectly.

Technical parameters H80-50

-

Guide Width: 80 mm

-

Max Load: 50 kg

-

Pitch: 190 mm

-

Synchronous Wheel Spec: STD5M-38Z

-

Recommended Speed: ≤ 2 m/s

-

Customized Length: Up to 6 meters

-

Input Torque: ≤ 13.5 N·m

-

Belt Spec: PU-5M-33 (steel wire)

-

Straightness: 0.05 / 300 mm

-

Applicable Motors:

-

Stepper Motor: 86 / 110 (Direct Connection)

-

Servo Motor: 400W/750W/1000W/1500W (Direct Connection)

-

-

Suggested Length Adjustment: Effective stroke + 520 mm (increments of 50 mm, e.g., 1000 mm, 1050 mm, 1100 mm)

This is the technical summary for the H80-50 linear motion module. If you require the full data sheet of the technical parameters, please contact us.

Features

-

High Precision – Engineered for accurate, repeatable motion in demanding applications.

-

Custom Lengths (up to 4 meters) – Tailored to fit your exact design and space requirements.

-

Corrosion-Resistant – Built with materials that withstand harsh environments and extend service life.

-

Maintenance-Free Operation – Designed for long-term use without regular servicing.

-

Ultra-Quiet Performance – Operates smoothly with minimal noise, ideal for sensitive settings.

-

Low Vibration – Ensures stable, consistent movement even at high speeds.

-

Trusted Reliability – Proven performance with minimal downtime across industries.

-

Long-Lasting Durability – Withstands continuous use under heavy loads and extended cycles.

-

Modular & Expandable – Easily integrates with accessories, sensors, and multi-axis systems.

Applications

-

Robotic Arms – Enables precise, repeatable linear motion for multi-axis automation.

-

3D Printers – Supports smooth, high-speed movement for accurate layer deposition.

-

CNC Router Machines – Ensures stable, rigid travel for cutting, milling, and shaping tasks.

-

Pick-and-Place Systems – Delivers fast, accurate positioning for high-throughput assembly lines.

-

Adhesive Dispensing Systems – Maintains controlled motion for uniform glue application.

-

Automated Painting Machines – Provides smooth, vibration-free movement for even coatings.

-

Packaging Equipment – Supports efficient and synchronized operations in automated packing lines.

-

Industrial Coding & Labeling Machines – Enables precise product marking and serialization.

-

Gantry Robots – Ideal for large-area, multi-axis systems requiring synchronized linear travel.

How to order

-

Tell Us About Your Project

Share your application details, goals, or challenges—our team is here to help. -

Provide Key Specs

Let us know the load weight, stroke length for each axis, travel speed, structure type, or environmental requirements. -

Receive a Tailored Quote

We’ll assess your needs and send you a detailed cost estimate—fast and accurate. -

Confirm & Start Production

Once payment is received, we’ll move your order into production with precision and care. -

We Handle the Shipping

We arrange safe and efficient delivery to your door, anywhere in the world.

-

Share Your Feedback

Your input matters—let us know how we did so we can keep improving.

🖨️ Best Settings for an Industrial Inkjet Printer

Maximize clarity, adhesion, and speed—without compromising reliability.

1. ✅ Print Resolution (DPI)

Recommended: 300–600 DPI for most industrial uses.

Use 600+ DPI when printing barcodes, fine text, or detailed graphics.

Higher DPI gives sharper prints but may reduce speed.

2. ✅ Ink Type & Firing Voltage

UV, solvent, or water-based inks must match the substrate.

Firing voltage must be calibrated to the ink viscosity and temperature.

Typical firing voltage range: 20–35V depending on the head type.

3. ✅ Drop Size (Picoliters)

Smaller drops (6–12 pL): For fine detail and smooth gradients.

Larger drops (25+ pL): For high-speed, high-coverage applications.

Most industrial systems allow multi-drop tuning for layered control.

4. ✅ Head Height / Print Gap

Ideal: 1–2 mm from the surface.

A consistent, minimal gap improves accuracy and prevents overspray. Higher gaps reduce sharpness and can cause misfires.

5. ✅ Substrate Feed Speed / Conveyor Speed

Adjust based on resolution and ink drying time.

Typical range: 15–60 m/min for packaging, slower for detailed prints.

Use encoder feedback for synchronized motion with print commands.

6. ✅ Drying/Curing Settings

UV inks: Use LED UV lamps with correct intensity and exposure.

Solvent-based: Require heated air or IR dryers.

Proper drying ensures adhesion and prevents smearing at high speeds.

7. ✅ Software Settings / Image Processing

Enable grayscale control, halftoning, or variable drop control depending on the job.

Calibrate color profiles for consistency across materials.

🧠 Pro Tips:

Run frequent nozzle checks and auto-clean cycles to prevent clogging.

Use a closed ink system with degassing to avoid bubbles and ensure flow.

Keep the environment dust-free and temperature-controlled for consistent quality.

✅ Bottom Line:

Your print quality is only as good as your tuning. Optimize resolution, ink control, gap, and speed for your material—and use automation and feedback where possible.

Need help integrating your inkjet head into a motion system like a Cartesian robot? We can help you match your printer, motion platform, and substrate handling perfectly.