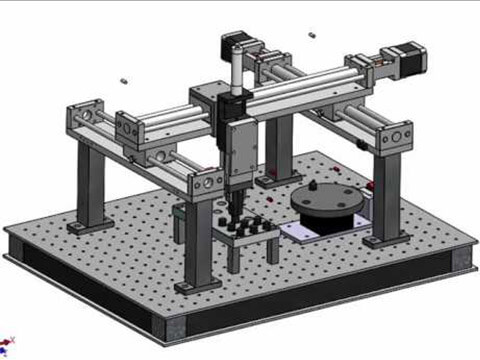

Automation assembly line usually have a working station, our linear rail can meet your requirements on it. The linear rail payload is range from 6kg to 35kg, it can be used as a pick and place robot, automated filling machine or glue dispenser machines.

CCM linear rails advantages at a glance:

Lubrication-free

low noise and smooth sliding

Resistance to dirt

Long service life

Corrosion-resistant

high accuracy

Especially suitable struture for use in automated working station

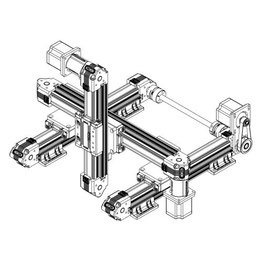

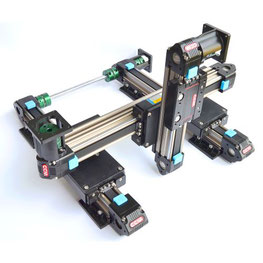

We offer motorized stages that can be assembled into many different configurations; for example, XY stages, XYZ stages . We list a few common XY stage combinations here, but you can select your own combination of family, travel and lead screw pitch in each axis to build the stage you need. We ship multiple stages un-assembled to avoid damage to the moving parts. Our families of linear stages are listed below. Please refer to the individual product family web page for specifications.

versatile design for various configuration. The Length of linear rail can be customized as per your requests.

1. XY LINEAR STAGE (X axis vertical)

2. XYZ LINEAR STAGE

Application examples

Recommended linear guide rails

CCM linear modules are applied in multiple fields, including robots, camera track, laser engraving and cutting, glue dispenser, 3D printer, aerospace, laboratory test, scanning, indexing and positioning, moving sensors, automation, factory conveyor.

The features of CCM linear module/ linear guide/ linear rail/ linear actuator are

1) high accuracy, 2) customized length up to 6 meters, 3) anti-corrosion,

4) maintenance-free, 5) noiseless, 6) low vibration, 7) high reliability, 8) high durability,

9) high speed up to 4.5M/s.