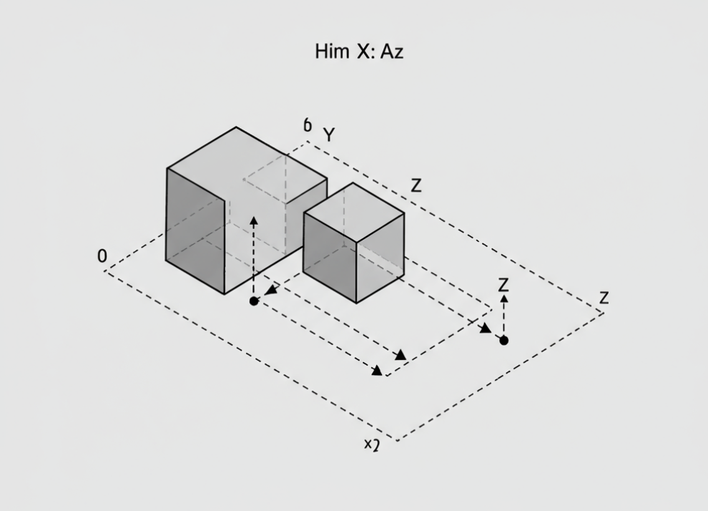

Cartesian robots move in straight lines along the X, Y, and Z axes, following the Cartesian coordinate system. Unlike articulated arms with multiple rotary joints, these systems use linear actuators or guide rails to position tools or end-effectors with high repeatability. Their predictable motion, large work envelopes, and straightforward programming make them popular in applications like pick-and-place, CNC machining, 3D printing, and inspection.

👉Ready to explore Cartesian robot solutions? Contact our engineering team for advice on integrating linear modules into your automation project.”

What Is a Cartesian Robot?

-

Definition: A Cartesian robot consists of orthogonal axes (X, Y, Z) so the end-effector moves in straight lines along each axis.

-

Also Known As: Gantry robot, linear robot, XYZ robot.

-

Core Idea: Use independent linear slides or actuators on each axis to reach any point in a rectangular/cubic work envelope.

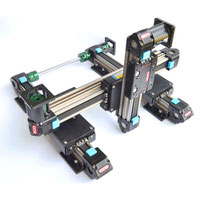

Structures & Main Components

1. Linear Guide Rails or Actuators

-

Provide precise straight-line motion. Drive types: belt-driven, ball screw, rack & pinion, roller-type.

2. Frame or Gantry Structure

-

Rigid aluminum/steel profiles forming base and supports; overhead beams for large span

3. Motors & Drives

-

Stepper or servo motors sized to load, speed, acceleration.

-

Pro Tip: Ensure proper motor-to-load inertia matching to avoid missed steps or stalling.

- Why my stepper motor gets hot?

4. Controllers & Electronics

- PLCs, motion controllers, or PC-based systems for coordinated commands. Feedback: encoders, limit switches.

5. End-Effector or Tooling

- Grippers, dispensing heads, cutting tools, or sensors on Z-axis carriage. Consider weight for rigidity.

6. Sensors & Safety Devices

- Limit/home switches on each axis; proximity or optical sensors for detection or vision integration.

- What is the difference between photoelectric sensor and proximity sensor?

Need help specifying rails, motors, and controllers? Contact our experts for a tailored Cartesian design.

How Does a Cartesian Robot Work?

- Coordinate-Based Motion: Controller calculates X, Y, Z positions in straight lines.

- Axis Sequencing: Each axis moves independently but coordinated (e.g., move X then Y then Z, or interpolate straight lines).

- Programming Simplicity: Kinematics trivial: position = (X, Y, Z). No inverse kinematics complexity.

- Modular Expansion: Add axes (e.g., rotary) or extend travel by lengthening rails or gantry beams.

Common Applications

1. Pick-and-Place and Assembly

- Moving parts between stations, loading/unloading conveyors or fixtures.

- Highly repeatable; used in electronics, packaging, pharma.

2. CNC Machining & Laser Cutting

- X–Y motion for tool paths; Z-axis for depth. Large tables/gantries for milling, engraving, cutting.

3. 3D Printing & Additive Manufacturing

- Precise layer-by-layer deposition; customize build volume via rail length.

4. Inspection & Vision Systems

- Position cameras/sensors over parts for quality control.

- XYZ Arm robot on optical inspection system

5. Laboratory Automation

- Liquid handling, sample transfers. Cleanroom Cartesian systems for biotech/pharma.

6. Packaging & Palletizing

- Gantry robots move packaging materials, fill containers, stack pallets. Overhead mounting saves floor space.

- 3-Axis Linear Module for Vertical Auto Doffing Machines

Advantages Of Cartesian Robots

Easy Programming & Control: Straightforward coordinate commands; minimal kinematic math.

Large, Customizable Work Envelope: Scale by lengthening rails or adding gantry beams.

High Precision & Repeatability: Rigid linear guides ensure tight tolerances.

Cost-Effective for Large Areas: Lower cost than multi-axis arms for broad rectangular workspaces.

High Payload Capacity: Overhead or supported frames handle heavier loads directly on linear guides.

Modular & Flexible: Mix-and-match axis modules; reconfigure for new tasks without full redesign.

Limitations & Considerations

Footprint & Space: Requires linear space; frame can be bulky vs. compact arms.

Speed on Complex Paths: Best for straight-line moves; less suited for complex curves that articulated arms handle natively.

Installation & Alignment: Precise installation of rails/frames is critical to avoid binding or wear.

Environmental Factors: In dusty/harsh settings, ensure seals and maintenance for linear guides.

Cost for Very Long Travel: Extremely long rails can be expensive and may need supports to prevent deflection.

Pro Tip for Professionals: Use FEA or deflection calculations when designing large gantries to maintain rigidity.

Cartesian Vs Other Robot Types

| Feature | Cartesian Robot | Articulated Robot | SCARA Robot | ||

| Motion Type | Straight-line XYZ | Rotary joints enabling curves | Planar XY with vertical Z | ||

| Work Envelope |

|

Spherical or complex shapes | Cylindrical | ||

| Programming | Simple coordinate commands | Inverse kinematics required | Moderate complexity | ||

| Payload Capacity | High for size (rigid frame support) | Moderate, varies by joint design | Moderate | ||

| Speed | Fast for straight moves; limited curves | High for complex paths | Very fast planar moves | ||

| Cost |

|

Higher initial cost and complexity | Mid-range | ||

| Applications | CNC, pick-and-place, 3D printing | Welding, painting, complex assembly | Assembly, 2D pick-and-place |

Design Tips For Engineers

Select Appropriate Linear Guides: Consider load, speed, precision, environment.

🔗 Link: “Top 5 Most Popular Structures of Linear Rail”.

Frame & Support Design: Ensure rigid supports, minimal deflection across travel; use proper bracing.

Motor & Drive Sizing: Match motor torque/speed to load inertia and desired acceleration; include safety margins.

🔗 Link: “Troubleshooting Common Stepper Motor Issues”.

Cable Management: Plan drag chains or overhead carriers to avoid snagging on long gantry spans.

Sensor Integration: Add home/limit switches, safety interlocks, vision or proximity sensors.

🔗 Link: “XYZ Arm Robot Applied on Optical Vision Inspection System Machine”.

Control Strategy: Use a controller/PLC capable of synchronized multi-axis control with sufficient I/O and protocols.

Maintenance Considerations: Provide easy access for lubrication, inspection, replacement of wear parts.

Prototype & Test Early: Build mock-up or simulation to validate kinematics/performance before full-scale build.

Frequently Asked Questions (FAQ)

Q1: Are Cartesian robots suitable for heavy loads?

-

Answer: Yes—when designed with robust linear guides and rigid frames, Cartesian systems can handle significant payloads, often more than articulated arms of similar size.

Q2: How do I choose between belt-driven vs. screw-driven axes?

-

Answer: Belt drives offer higher speed and longer travel at moderate precision; screw drives (ball or lead screw) deliver higher thrust and positioning accuracy but may limit top speed. Match drive to application’s requirements.

-

🔗 Link: “Quick and Easy: How I Choose the Right Belt-Driven Linear Guide Rail”.

Q3: Can I mount a Cartesian robot overhead?

-

Answer: Yes. Overhead mounting saves floor space and allows loads to be carried directly from above. Ensure safety guarding and robust frame design.

Q4: What maintenance do Cartesian robots need?

-

Answer: Regular inspection of linear guides for debris, lubrication as specified, checking belt tension or screw backlash, verifying sensor function. Design modules for easy access.

-

🔗 Link: “Troubleshooting Common Stepper Motor Issues” or “Linear Rail Maintenance Tips”.

Q5: How scalable are Cartesian robots?

-

Answer: Very scalable. You can extend rail lengths, add axes (rotary or additional linear), or combine multiple gantry units for larger systems. Plan frame supports and controller capacity accordingly.

Conclusion

Cartesian coordinate robots are foundational in automation due to their simplicity, precision, and adaptability. Beginners gain a clear understanding of straight-line motion systems, while professionals get design tips to build robust, scalable solutions. By following best practices for guide selection, frame design, and control integration, your Cartesian robot project can achieve high performance and reliability.

Ready to implement a Cartesian robot in your facility? Contact our engineering team for tailored solutions, fast quotes, and expert guidance.”

🔗 Related Articles to Link Here (end of post):

7. “Custom Linear Motion Modules: https://www.ccmrails.com/products/customized-service/

“What Is a Gantry Robot?” →

https://www.ccmrails.com/2019/01/17/what-is-gantry-robot/“Top 5 Most Popular Structures of Linear Rail” →

https://www.ccmrails.com/2019/04/12/top-5-the-most-popular-structures-of-linear-rail/“Quick and Easy: How I Choose the Right Belt-Driven Linear Guide Rail” →

https://www.ccmrails.com/2025/05/20/quick-and-easy-this-is-how-i-choose-the-right-linear-guide-rail-belt-driven/“XYZ Arm Robot Applied on Optical Vision Inspection System Machine” →

https://www.ccmrails.com/2021/11/01/xyz-arm-robot-applied-on-optical-vision-inspection-system-machine/“3-Axis Linear Module for Vertical Auto Doffing Machines” →

https://www.ccmrails.com/2021/12/28/3-axis-linear-module-for-vertical-auto-doffing-machines/“Troubleshooting Common Stepper Motor Issues” → https://www.ccmrails.com/2021/10/06/how-to-see-the-stepper-motor-overload/

Customization Service

At CCM Technology, we understand that every project is different, which is why we offer tailored solutions designed to fit your exact specifications. Whether you need a system built to handle high loads, withstand harsh environments, or meet specific space constraints, our custom linear guide rails deliver exactly what you need.

Write a comment